Coffee Finishing Tanks are a crucial step in producing Ready To Drink (RTD) Coffee products that can be bottled, distributed, and enjoyed. After the Coffee has brewed, the Coffee can be transferred to a finishing tank where flavors, sweeteners, dairy, and other additives can be added to the Coffee product. Optionally, a mixer can be added to the tank for better emulsion. The Coffee can then be canned, bottled, pasteurized, kegged, or enjoyed on the spot!

Portland Kettle Works’ tanks have earned a reputation as some of the most consistent performing and eye-catching tanks to be found anywhere. Our finishing tanks will shorten your workday while continuing to provide a superior return on your investment for years to come.

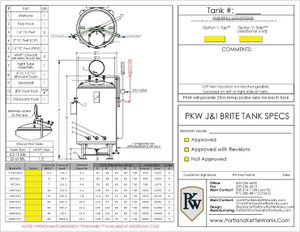

Features:

- Integrated volumetric sight glass saves time and effort for tax determination

- Insulated vessels add efficiency, minimize heat-loading, and reduce safety hazards

- Sight glass is fully Clean-In-Place ready without additional components

- Equipped with a 4” (10 cm) ultimate drain for rapid easy clean-out

- Optional Mixing attatchment and motor to increase consistency and flavor

- All coffee finishing tanks are rated to 14.7 PSI (1 bar) operating pressure

- All coffee tanks can be either single-walled or double-walled (jacketed and insulated)

- 100% food-grade 304 and 316 stainless steel, 12-gauge inner tank steel (on jacketed/insulated tanks) and 14-gauge shell materials

- Top-mount manway (optional side-mount configurations available)

- Complete thermal insulation of side walls and cones

- All welds are blended and finished to a sanitary food-grade finish

- Innovative design registers zero stress on the internal structure of the tank

- Integrated Clean in Place (CIP) systems allow rapid and convenient cleaning

- Industry leading American design, engineering, and fabrication

Sizes offered:

| Gallons | Liters |

| 30 | 120 |

| 60 | 240 |

| 125 | 475 |

| 180 | 700 |

| 230 | 875 |

| 350 | 1300 |

| 500 | 1900 |

| 680 | 2600 |

| 1000 | 3800 |

| 1300 | 5000 |

| 2000 | 7600 |

| 2500 | 9500 |

| 3000 | 11400 |

| 4000 | 15200 |

| 5000 | 19000 |

Other capacities available upon request

Every Finishing Tank is equipped with:

-

- pressure relief valve

- blow-off/ clean-in-place (CIP) tube

- CIP spray ball

- sample valve

- butterfly valves

- TC clamps, gaskets and clamps

- 90-degree elbows

If you have any questions regarding our Coffee Finishing tanks, feel free to contact us. We are also available by phone (503)-310-1383.